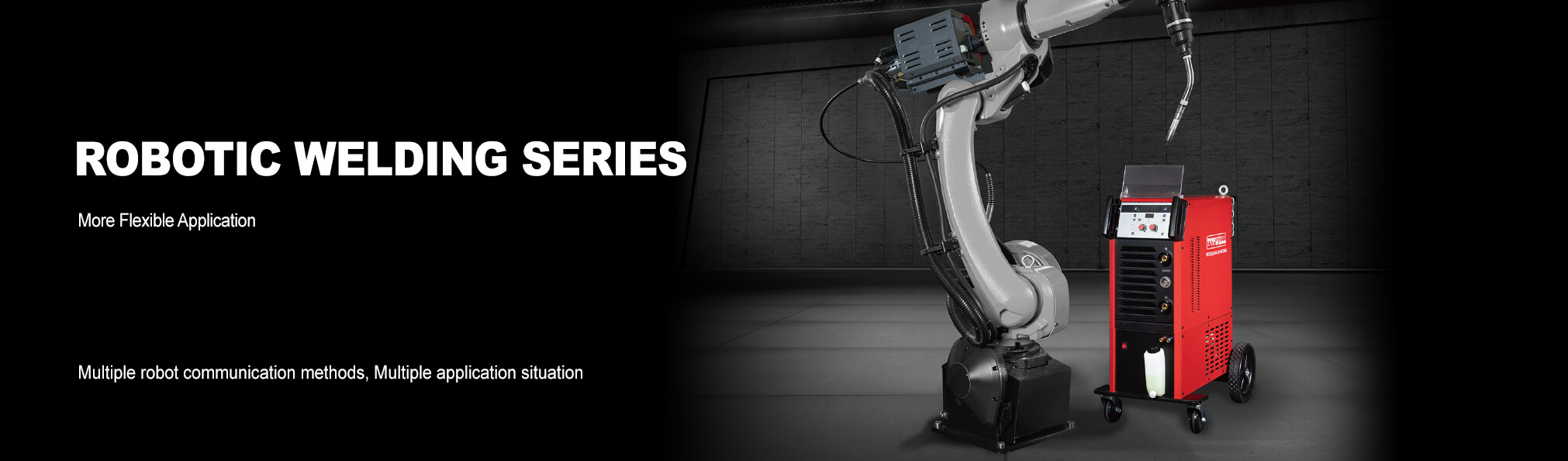

Multiple robot communication methods

Adapt to a variety of robot communication, achieve seamless integration with different brands of robots.

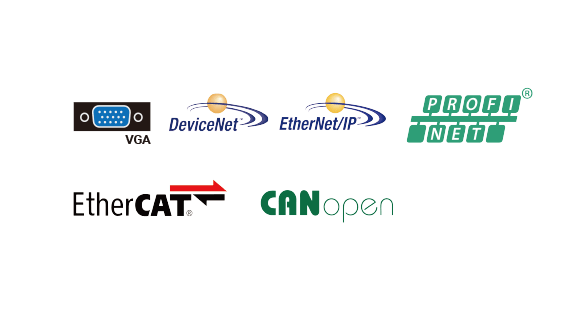

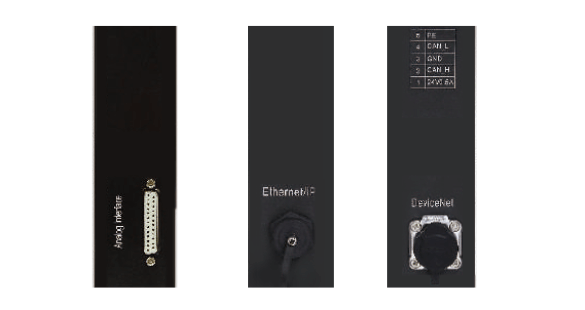

| Robot communication modes | ● Standard ○ Optional |

|||||

|---|---|---|---|---|---|---|

| Analog | Enternetlp | DeviceNet | CAN | CANOPEN | RJ485 | |

| ● | ○ | ○ | ○ | ○ | ○ | |

Dedicated communication box for fast and reliable transmission.

Long-distance welding

Can remotely display and adjust the key parameters of welding without being limited by the cable. The length of the control cable is greater than 25m, suitable for long-distance welding work.

Intelligent compensation makes welding more stable, especially suitable for oversized workpiece welding occasions.

Accurate arc tracking feedback

The welding machine parameters interact with the robot in real time with high frequency, which perfectly supports robot arc tracking, which is suitable for medium and thick plate robot welding.

Fast communication speed with the robot, real-time detection signal , high repeatability of positioning, no need to recalibrate after a slight collision, can be immediately resumed for use.

It can manage and collect welding production data in real time on demand, and realize detailed supervision and pre-control of the production process.

Stable wire feeding system

The wire feeder is equipped with wire feeding, wire unwinding, gas detection button function. Code disc feedback & back EMF feedback switching to have precise feeding speed adjustment.

The welding machine panel can display the "wire feeding resistance coefficient", which conveniently reminds customers to check the poor wire feeding system so as not to affect the welding effect.

In PushPull Systems, welder directly drive torch's motor, keep with wire feeder motor torque synchronization and speedsynchronization.

Multiple welding process

Cover all welding process

For robotic applications, TOPWELL has upgraded a range of machines, including: MIG welding, TIG welding, SAW welding and plasma cuting.

Robotic MIG Welding

Robotic TIG Welding

Robotic SAW Welding

Robotic Plasma Cutting

Multiple Robotic applications

⬤ Robotic MIG Welding Solutions

TOPWELL uses professional welding machines to cooperate with industrial robots, provides cutting-edge innovative welding processes and stable wire feeding system, obtains perfect welding results with ultra-high droplet speed and precision, can achieve full-position welding. When robotic welding, you will achieve consistent, high-quality welding results, and maximize productivity for multiple industrial welding situations.

Options

PROMIG Series / PROWAVE Series / Steelmate Series

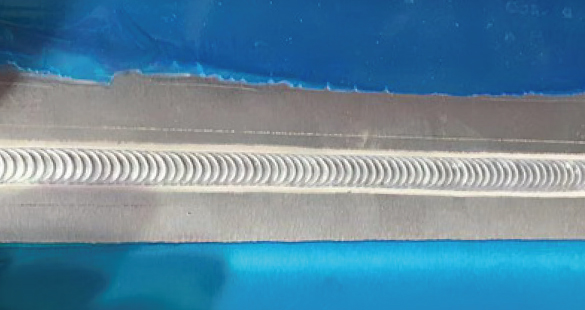

Welded by PROMIG 360SYN DPulse

Process: HSS

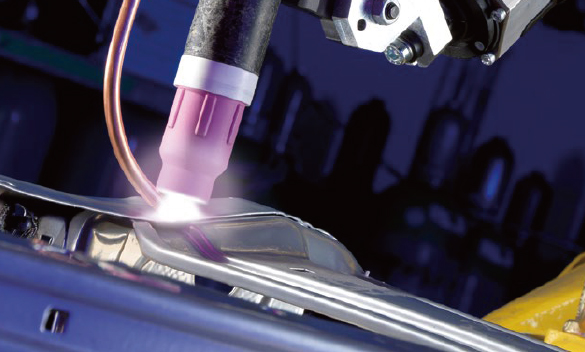

⬤ Robotic TIG Welding Solutions

In TIG robot welding, the unique MIX TIG process and precise waveform control of TOPWELL welders, communicate with stable robots, provide excellent welding quality and perfect weld appearance.

Options

PROTIG Series / MASTERTIG Series

Welded by MasterTIG 500CT

Process: MIX TIG

⬤ Robotic Plasma Cutting Solutions

High-performance plasma cutters paired with flexible robots can complete more difficult tasks and meet the needs of high-precision cutting. At the same time, it improves efficiency and leads to a safer operating environment.

Options

TOPWELL MAX Series

Process: Plasma Cutting

⬤ Robotic SAW Welding Solutions

TOPWELL's heavy duty power sources are designed to semiautomatic and automatic welding, the precise control of machine delivers superior arc for Submerged Arc (SAW) , recudes heat affected zone, minimizes distrotion and increases mechanical properties.

Options

SubArc-1000DC/1250DC

SubArc-1000XD/1250XD

Process: SAW

LET'S STAY IN TOUCH

Get updates on sales specials and more

FOLLOW US

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号